Our low water content dehydrating system using a slide shaft screw press dehydrator received the 35th Environmental Machinery Award "METI Industrial Science and Technology Policy and Environment Bureau Director-General Award."

16.Jun.2009

Ebara Engineering Service, Ltd. was honored by the Japan Society of Industrial Machinery Manufacturers for its "low water content dehydrating system using slide shaft screw press dehydrator" in the 35th Environmental Machinery Award with "METI Industrial Science and Technology Policy and Environment Bureau Director-General Award." This is the second award given to this system following "The Japan Machinery Federation Chairman's Award" announced in February this year on the 29th (FY2008) commendation by the Japan Machinery Federation for excellent energy saving systems.

Our low water content dehydrating system using a slide shaft screw press dehydrator reduces the sludge water content to less than 70 percent by using a slide shaft screw press dehydrator and gravity thickener. This cannot be achieved with conventional screw press dehydrating technologies. Through this breakthrough, drastic energy savings and a huge reduction in CO2 emissions from the whole facility can be achieved. By introducing this system, it is possible to recover a combustion improver, which is one of the target recovery resources in sludge regeneration treatment facilities. Therefore, projects adopting this system are eligible for subsidies from the Ministry of Environment within the framework of the Recycle-Oriented Society Promotion Project. To date, we have delivered 22 units to 17 projects operated by nationwide community waste treatment and sludge regeneration treatment facilities, mainly. Besides, this model has been widely adopted in sewage discharge facilities and private organizations requiring the dehydration of organic sludge and such like, and demonstrated its excellent features.

Effect

- Drastically reduces water content

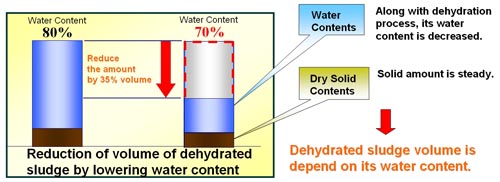

When dehydrating human wastes directly with a conventional centrifugal dehydrator, the water content of the dehydrated cake is 80 percent. By using this system, the water content can be reduced to less than 70 percent. - Drastic reduction of dehydrated cake disposal costs is possible.

The volume of dehydrated cakes depends on their water content. When the water content is reduced from 80 to 70 percent, the volume of the dehydrated cakes is reduced by approximately 35 percent, which results in a drastic reduction in disposal costs. - Significant contribution for prevention of global warming

By reducing the volume of dehydrated cakes, various energies required for disposal can be reduced, which also helps to reduce CO2 emissions.

Volume reduction of dehydrated sludge using low water content dehydrating system

Characteristics

- Adoption of thickener

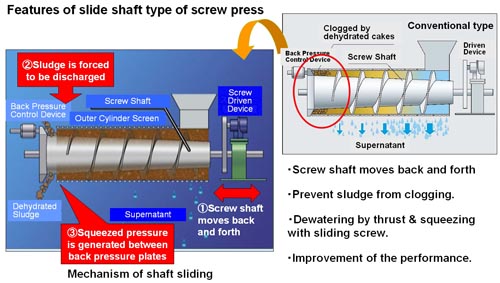

By having a separate arrangement with the thickening mechanism, a stable performance can be ensured even when handling low density sludge or when there is a fluctuation in the sludge feed flow. - Adoption of slide shaft mechanism

By adopting a slide shaft mechanism, the problem of constriction that is specific to screw press dehydrators can be eliminated and the sludge can be dehydrated more. - Facility to remove residue is unnecessary

Because solid residue in the sludge feed helps to improve the dehydration performance in the case of a slide shaft screw press dehydrator, there is no need to remove residue from sludge even when treating human wastes including those with a high amount of solid residue.

Characteristics of slide shaft screw press dehydrator

Standard flow of low water content dehydrating system

Local Navigation Start

Right Column Start